Sceptre Power Sdn Bhd

No. 49, Jalan TS 6/5,

Taman Industri Subang,

47510 Subang Jaya,

Selangor, Malaysia.

No. 49, Jalan TS 6/5,

Taman Industri Subang,

47510 Subang Jaya,

Selangor, Malaysia.

+603-8011 6618

Services

Ceramic Coatings for High-Emissivity and Corrosion-Resistance

SENTRO TECHNOLOGIES USA, LLC specializes in high emissivity and corrosion protection ceramic coatings.SENTROCOAT C, M, CM high emissivity coatings (water-based)

The SENTROCOAT line of water-based high emissivity coatings are blackbody formulations designed to significantly improve the thermal efficiency of radiant section tubes of furnaces, heaters and boilers in the Oil & Gas industries.

Energy savings in the range of 3–10% are typical using our coatings.

SENTROCOAT CP-1, CP-2 corrosion resistant coatings (solvent-based)

SENTRO’s Corrosion-Resistant Paint SENTROCOAT CP series coatings are formulated using an advanced solvent-based silicone resin combined with inorganic fillers and pigments

to offer continuous temperature resistance to 1100 °F (593 °C) and intermittent resistance to 1200 °F (649 °C).

These coatings are single-part, heat curable systems that adhere to a wide range of materials including metals, ceramics, glass, quartz, and refractories, and offer outstanding resistance to outdoor weathering, UV light, salt spray corrosion, oxidation, some chemicals, and thermal shock.

SENTROCOAT CP Line HIGHLIGHTS

SENTRO’s Corrosion-Resistant Paint SENTROCOAT CP series coatings are formulated using an advanced solvent-based silicone resin combined with inorganic fillers and pigments

to offer continuous temperature resistance to 1100 °F (593 °C) and intermittent resistance to 1200 °F (649 °C).

These coatings are single-part, heat curable systems that adhere to a wide range of materials including metals, ceramics, glass, quartz, and refractories, and offer outstanding resistance to outdoor weathering, UV light, salt spray corrosion, oxidation, some chemicals, and thermal shock.

SENTROCOAT CP Line HIGHLIGHTS

- Single-Part, No Mixing

- Low Viscosity

- Maximum Use Temperature, 1100 °F (593 °C)

- Intermittent Use Temperature, 1200 °F (649 °C)

- Bonds to Ceramics, Glass, Quartz, Metals

- Excellent Resistance to Moisture & Salt Spray

- Resists Thermal Shock

- Resists Ultraviolet Light

- Good Chemical Resistance

- Solvent-Based

Photo Gallery

Coating application of SENTROCOAT M (high-emissivity) in action

Step I : sandblast surface cleaning till “near white metal” of a furnace coil

Step II: applying 1st layer

Step III: applying 2nd layer

Step I : sandblast surface cleaning till “near white metal” of a furnace coil

Step II and III: applying 1st and 2nd layers

Measurement of Wet film thickness

Measurement of Dry film thickness

Fuel Additives for Coal-Operated Boilers in Power Plants

Improved efficiency and reduced slagging and corrosion through SENTROJET chemical injection into coal-fired boiler or furnaceGENERAL

SENTRO TECHNOLOGIES USA, LLC provides a simple, flexible and cost-effective solution to problems arising from the combustion of Coal or Bio-Fuels.

Suggested applications: coal-operated Steam Boilers, Cement Furnaces, or any other coal-operated equipment

Our method is injecting SENTROJET product directly on the coal belt (pre-combustion) or directly into the combustion chamber or the flue gas stream (post-combustion) to produce chemical reactions to oxidize, neutralize and convert residues from combustion which would otherwise increase fouling, corrosion and air pollution.

Reducing fouling, slagging and corrosion will increase the thermal efficiency of the boiler or the furnace, and as a result will reduce fuel consumption, save energy, and reduce pollution.

SENTRO’s cleaning system for heat transfer surfaces and emissions are the result of practical applications combined with continuous research and development.

Example of the problem: Slagging on boiler’s tubes

YOUR CHALLENGES

As a result of combustion and depending on the type of fuel and temperatures, vanadium, alkali metal sulfates and alumina silicates will form hard deposits, unburnt carbon and sulfur will form softer and sometimes sticky deposits which will attract other unburnt residue, thereby increasing the thickness of deposits even more. This leads to reduced heat-transfer, blockage of flue gas passages and damage to brickwork.

PROFILE IN LOW TEMPERATURE

Some of the sulfur in the fuel will be oxidized to SO3 which will react with water vapor to form sulfuric acid condensing on surfaces when temperatures are below its dew point. This can also occur when the temperature of the flue gas is above the dew point and the deposits insulate the heat-exchange surfaces. Air-heaters, ducting and stacks are particularly susceptible to this type of corrosion.

PROFILE IN HIGH TEMPERATURE

Vanadium pentoxide with a low melting point will form extremely hard deposits mostly within the super-heater zones. Such deposits are difficult to remove and will give rise to corrosion. Vanadium pentoxide is also a catalyst in the conversion of sulfur dioxide to sulfur trioxide.

Smut, dust and NOx emissions will attract complaints from residents living nearby and these emissions will sometimes exceed limits set by the legislators. The main cause of acidic smutting is unburnt carbon carrying sulfuric acid from the stack. Dust is the particle residue from combustion which escapes from the stack where no or ineffective electrostatic precipitators are installed. The higher the temperature of the combustion, the more NOx is formed. Particularly, the emissions of dust and NOx are subject to tight legislative control.

Slagging inside the boiler

.jpg)

THE SENTRO TECHNOLOGIES SOLUTION

SENTROJET chemical will oxidize unburnt carbon, reduce sulfates and convert vanadium pentoxide to vanadates with a much higher melting point. Deposits will become dry, powdery and disintegrate. They therefore lose their adhesion to heatexchange surfaces.

This complements the air/steam/water soot-blowing, if exist, and increases their efficiency.

SENTROJET chemical will neutralize the sulfur trioxide in the flue gas by the continuous injection of a product containing a water-soluble magnesium compound and which will lower the sulfuric acid dew point temperature to any level required to avoid condensation and therefore corrosion.

Any residue will be dry, powdery and easy to remove. The SENTROJET treatment will also ensure the conversion of vanadium pentoxide to non-corrosive vanadates with such a high melting point that deposits become brittle and flake off. The reaction of SENTROJET with vanadium pentoxide will also inhibit the formation of sulfur trioxide and therefore sulfuric acid.

By oxidizing the carbon deposits, SENTROJET will greatly reduce or eliminate the problem of acid smutting. After oxidation of the unburnt carbon remaining dust particles are less likely to escape into the atmosphere, as their density is greater than that of ordinary soot. The efficiency of separators and electrostatic precipitators will be improved since residues are dry and friable. NOx must be measured accurately and can be reduced by SENTROJET to any level required to satisfy current legislation.

Post-Combustion injection of chemicals directly through the boiler’s wall

.jpg)

Post-Combustion injection of chemicals near the burner

.jpg)

THE SENTRO TECHNOLOGIES TREATMENT IS SIMPLE AND FLEXIBLE

Installation and operation can start at any time without taking the plant out of service and it does not matter whether the plant is in a clean or fouled condition.

The following optional treatment systems are available:

- Continuous

- Intermittent but regular (chemical soot-blowing)

- During start-up and shutdown of plant (24-48 hours)

- Crash dosing to avoid unscheduled shutdowns and to extend runs

- Crash dosing to make plant easier to clean

-

Crash dosing to keep plant dry for longer periods during programmed shutdowns

Our technicians will advise the best product, quantity and injection system to meet your requirements. They will supervise the installation and assist your operators with the help of flue gas analyzers and dew point meters to ensure optimum benefit to the customer.

BENEFITS OF SENTROJET TREATMENT

- Saves energy (less fuel consumption, estimated by 3-10%)

- Better fuel efficiency without corrosion

- Reduced cost of soot blowing

- Greater output and availability of plant

- Reduced cost of cleaning and maintenance

- Dry-cleaning instead of water-washing

- Less damage to brickwork

- Safer and better working conditions

- Less pollution

THE ECONOMICS OF SENTRO TECHNOLOGIES

The use of SENTROJET will significantly reduce costs through fuel savings. A SENTRO TECHNOLOGIES representative will assist you in calculating these and other benefits. Estimated fuel saving is 3-10%, depending on: current fuel consumption, burners’ efficiency, overall furnace efficiency, combustion profile, furnace configuration, and other efficiency and structural variables.

SENTROJET SAFETY DATA SHEETS

These are supplied for each product separately and will indicate details of packaging, handling, transportation and storage as required.

Chemicals-Air manifold with flow meters and pressure gauges

Pre-Combustion injection of chemicals on the coal

.jpg)

TECHNICAL ASPECT OF SENTROJET TREATMENT

SENTROJET is the form of an aqueous solution, injected on the coal belt or into the flue path of the boiler or furnace. If post-combustion, injection is done at a point where the flue temperature is greater than 500°C.

Post-combustion injection is done by special lances and nozzles. The driving force for the injection is compressed air at a pressure of 5 to 6kg/cm2. If a compressed air facility is not readily available at the site a pump may be used as an alternative. However it must be assured that the injection pressure is 5 to 6 kg/cm2.

On injection into the hot zone, SENTROJET decomposes and vaporizes. The vapors travel to all parts of the boiler/furnace. It is these vapors of SENTROJET that, by chemical action, loosen and free adhering deposits.

SENTROJET, on decomposition, forms magnesium oxide (MgO), NO2, N2O and Copper II oxide (CuO), and water vapor. The MgO and CuO neutralize low melting point ash deposits by forming corresponding magnesium derivatives. The NO2 and N2O serve to oxidize carbon deposits forming carbon dioxide and elemental nitrogen.

The MgO and CuO also form a grey protective layer on the heat transfer surfaces and this helps in preventing, to some extent, further deposits of unburnt carbon and low melting point ash.

If any sulfuric acid forms due to the sulfur in the fuel the MgO and CuO neutralize this to form magnesium sulfate. SENTROJET treatment, while ramping down for shutdown or ramping up after start up, will significantly reduce the probability of corrosion.

It is during the shutdown and start up processes when there is maximum likelihood of flue temperatures falling below the dew point and, therefore, the greatest risk of corrosion.

If fuel contains vanadium the vanadium gets converted to vanadium pentoxide on combustion. Vanadium pentoxide acts as a catalyst for converting sulfur dioxide to sulfur trioxide. Sulfur trioxide reacts with water vapor to form sulfuric acid.

SENTROJET reacts with vanadium pentoxide to form magnesium vanadate. SENTROJET therefore removes the catalyzing agent that promotes sulfuric acid formation.

In some boilers or furnaces there is the problem of hot spot corrosion. Hot spots are formed when low melting point ash forms a hard insulating layer on the tube surface. Hot spots can lead to tube puncture. SENTROJET treatment removes low melting point ash deposits thus minimizing the possibility of hot spot corrosion.

Two levels of SENTROJET treatment need to be considered:

“clean-up” treatment

“keep clean” treatment

The “clean up” dosage is applicable for treatment of a dirty system.

The requirement of SENTROJET is computed as 0.3 liters of SENTROJET concentrate per ton of fuel consumed over 10 days.

Thus if the clean-up is required of a boiler or furnace system consuming 50 tons per hour of coal, than the quantity of SENTROJET is 50 X 24 X 10 X 0.3 = 3600 liters.

The computed quantity of SENTROJET is to be intermittently injected over a period of time of 10 days.

If only a section of the boiler or furnace is known to be fouled, the dosage of SENTROJET can be logically scaled down. For instance, if it is known that only the fire box of a boiler or furnace is fouled and the heat transfer area in the fire box is 50% of the total heat transfer area of the boiler/furnace the dosage applied can be 50% of the prescribed dosage.

When a boiler or furnace is clean and the aim is to sustain cleanliness the “keep clean” dosage of SENTROJET is applicable.

The monthly requirement of SENTROJET for keep clean is calculated as 0.1 to 0.15 liters of SENTROJET per ton of fuel consumed in a 7 day period.

Thus if a boiler/furnace system consuming 50 tons per hour of coal is to be kept clean, the quantity of SENTROJET required per month would be 50 X 24 X 7 X 0.1 = 840 liters to 50 X 24 X 7 X 0.15 = 1260 liters.

SUPPLEMENTING SENTROJET TREATMENT

On occasion, while SENTROJET treatment may loosen the deposits on heat transfer surfaces, the force of the flue gas may not be adequate to carry these away. In such instances injection of compressed air or high-pressure steam after each injection cycle would be of value.

ADVANTAGES OF SENTROJET TREATMENT

SENTROJET provides the boiler/furnace operator with a number of benefits. These include:

- The cleaning of the boiler/furnace is carried out On-Line without an unscheduled shutdown.

- Improved energy efficiency. Stack losses will be reduced.

- Restoration of lost capacity, in cases where loss of capacity is due to fouled heat transfer surfaces.

- Reduced corrosion rate.

- Increased interval between shutdowns, therefore providing greater system availability.

- Reduction, if not elimination, of soot blowing operations. SENTROJET treatment can be considered a type of chemical soot blowing.

- Reduced cleaning time when shutdowns are taken.

- Improved safety since the equipment’s operation is restored to prescribed design parameters.

- Reduced power consumption of FD and ID fans, since fouling increases pressure drops and therefore fan power requirement.

- Reduced air pollution since the SENTROJET treatment reduces acid formation and, therefore the possibility of “acid smutting”.

PRICING

(All prices are in $USD and Net of all Fees and Taxes)

Pricing and payment terms to be determined upon additional technical information which is required.

ON-LINE Acoustic Emission Inspection

Advanced Acoustic Emission (AE) Inspection ON-LINE or Off-LineSENTRO TECHNOLOGIES USA, LLC specializes in Acoustic Emission Inspection and Testing, which can be performed ON-LINE during normal operating conditions.

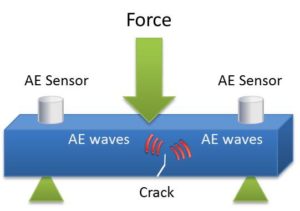

Acoustic Emission (AE) is a phenomenon of sound and ultrasound wave radiation in materials that undergo deformation or fracture processes.

Cracking, plastic deformation development, fracture and de-bonding of hard inclusions are examples of macroscopic sources of AE in metals.

Friction and impacts are examples of mechanical AE sources.

Detection of corrosion products by AE method

Applicable for:

- Piping – metal, concrete, plastics – all sizes, above ground or under ground

- Heat exchangers

- Storage tanks, including hazardous material

- Pressure vessels, including towers and reactors

- Isolated equipment

- FRP (Fiberglass) equipment (vessels, pipes)

- Glass lined equipment

Absolute identification of flaws and defects – size and location:

- Corrosion

- Micro-cracks

- Holes

- Blockages

- Deformation

Detection of micro-cracks by AE method

Our AE testing method is approved by:

- ASTM – American Society for Testing and Materials

- ASME – American Society of Mechanical Engineers

- European Committee for Standardization

- International Organization for Standardization

- Japanese Institute for Standardization

- Japanese Society for Nondestructive Inspection

Example of AE signals

.jpg)

ON-LINE AE Testing of a storage tank

Results – corrosion rate of storage tank bottom plates

AE Inspection of underground pipeline

.jpg)

AE Inspection of above-ground pipeline

AE Inspection of FRP pipeline

SENTRO AE high frequency sensors and amplifier

AE Inspection of a Reactor, total of 36 sensors installed

SENTRO AE Engineers in action

ON-LINE Dry Chemical Cleaning of ¡®fin-fan¡¯ Air Coolers

“On-The-Run” Dry Chemical Cleaning

SENTRO TECHNOLOGIES USA, LLC specializes in ‘fin-fan’ Air Coolers chemical cleaning during normal operating conditions.

There is no need to shut down the equipment, production continues normally.

Cleaning process applied on external tube surface, through the whole bundle from bottom to top.

If the blade is on the bottom (forced-draft type) we have to turn the blade off for approximately 30 to 45 minutes.

If the blade is on the top (induced-draft type) it stays running the entire time.

A Process of Chemistry & Physics

Cleaning is done by combination of mechanical effect and chemical effect – simultaneously.

The mechanical effect is non-aggressive abrasion over the tube and fin surface, to remove inorganic scale without damaging the surface or fins.

The chemical effect is a degreasing reaction between SENTROFIN chemicals and oil deposits, hydrocarbons, and other types of organic scale.

This innovative dry cleaning process is safe, environmental-friendly and cost effective.

We anticipate that the SENTROFIN On-Line Dry Chemical Cleaning of ‘fin-fan’ Air Coolers will deliver the following benefits and results:

- Cleaning is performed On-Line during normal operating conditions of the unit, there is no need to shut it down.

- Removal of scale and fouling from external tube surface, forced and induced type coolers, thereby increasing thermal efficiency (heat transfer). As a result, reducing process outlet temperature, increasing production rate and in case of variable speed motors reducing operating energy consumption (fan power).

- No Scaffolding required.

- No water, no water-treatment.

- No dry-Ice (no thermal shock to tubes and fins, especially to aluminum or copper fins)

- No foam or soap (no caustic stress corrosion cracking)

- No clean-up or disposal requirements

- No harmful chemicals (no negative environmental impact)

- No damage to tubes, fins, electrical motors, instrumentation.

- No confined space entry

Major Benefits

- Immediate increase of air coolers thermal efficiency

- Immediate increase of throughput / production

- Energy saving by reduced fan power (in a variable speed motors)

- Reduce temperature profile of the furnace or boiler (cell, bridge wall, stack)

- Pre-shut down activity – saves time and costs

- Saves maintenance activities (such as: scaffolding, water high pressure blasting etc..)

Our On-Line Cleaning Process is SAFE and Environmental Friendly:

- Developed over years of R&D and field experience

- Chemicals are Non-toxic, Non-hazardous, Non-corrosive, Non-poisonous, Non-flammable, Non-explosive, Non-transport regulated

- No damage to metallurgy, electrical motors, and instrumentation

- Chemicals completely dispersed, appear like steam

- Chemicals are compatible with all types of air coolers metallurgy

Photo Gallery

Dry cleaning in action – forced draft air cooler – bottom to top

.jpg)

Top view – chemicals disperse and appear like steam

.jpg)

Example of finned tubes before/after SENTRO dry chemical cleaning

.jpg)

Safety and Quality Control according to SENTRO’s Safety and ISO Standards

.jpg)

Examples of Tube and fins damages due to improper cleaning methods

Carbonates scale due to usage of fire-water for the cleaning – SENTRO guarantees NO DAMAGES to tubes or fins

.jpg)

Chemical damage to fins due to usage of caustic foam or soap – SENTRO guarantees NO DAMAGES to tubes or fins

.jpg)

Physical damage to fins due to usage of high pressure water jet – SENTRO guarantees NO DAMAGES to tubes or fins

SENTROFIN dry chemicals are non-hazmat, non-toxic, not regulated for transport

.jpg)

Physical damage to fins due to usage of high pressure water jet – SENTRO guarantees NO DAMAGES to tubes or fins

SENTROFIN dry chemicals are non-hazmat, non-toxic, not regulated for transport

.jpg)

SENTRO setup near the air coolers: Equipment, Chemicals, Air Compressor and Hoses – our footprint is small.

.jpg)

ON-LINE Dry Chemical Cleaning of Furnaces, Heaters, Boilers

“On-The-Run” Dry Chemical Cleaning

SENTRO TECHNOLOGIES USA, LLC specializes in furnaces, heaters and boilers chemical cleaning during normal operating conditions.

There is no need to shut down the equipment, production continues normally.

Cleaning process applied on external tube surface of both radiant and convection tubes (fire side).

We also dry-clean air pre-heating system, economizer, and other types of process equipment.

A Process of Chemistry & Physics

Cleaning is done by combination of mechanical effect and chemical effect – simultaneously.

The mechanical effect is non-aggressive abrasion over the tube surface, without damaging the surface, fins, or refractory.

The chemical effect is a neutralization reaction between alkaline SENTROMAX chemicals and the acidic scale, hot spots (usually sulfuric) and fouling deposits.

This innovative dry cleaning process is safe, environmental-friendly and cost effective.

We anticipate that the SENTROMAX On-Line Dry Chemical Cleaning of process furnaces, heaters, and boilers will deliver the following benefits and results:

There is no need to shut down the equipment, production continues normally.

Cleaning process applied on external tube surface of both radiant and convection tubes (fire side).

We also dry-clean air pre-heating system, economizer, and other types of process equipment.

A Process of Chemistry & Physics

Cleaning is done by combination of mechanical effect and chemical effect – simultaneously.

The mechanical effect is non-aggressive abrasion over the tube surface, without damaging the surface, fins, or refractory.

The chemical effect is a neutralization reaction between alkaline SENTROMAX chemicals and the acidic scale, hot spots (usually sulfuric) and fouling deposits.

This innovative dry cleaning process is safe, environmental-friendly and cost effective.

We anticipate that the SENTROMAX On-Line Dry Chemical Cleaning of process furnaces, heaters, and boilers will deliver the following benefits and results:

- Cleaning is performed On-Line during normal operating conditions of the unit, there is no need to shut it down.

- Removal of scale and fouling from external tube surface, Radiant and Convection tubes, thereby increasing thermal efficiency (heat transfer). As a result, reducing operating energy consumption and increasing production rate.

- No Scaffolding required.

- No water, no water-treatment.

- No dry-Ice (no thermal shock to tubes, especially to cast iron tube-supports)

- No foam or soap (no caustic stress corrosion cracking)

- No clean-up or disposal requirements

- No harmful chemicals (no negative environmental impact)

- No damage to tubes, fins, refractory, instrumentation.

- No confined space entry

Major Benefits

- Immediate increase of furnace or boiler thermal efficiency

- Immediate increase of throughput / production

- Energy saving by reduced fuel consumption

- Reduced emission / pollution

- Reduce temperature profile of the furnace or boiler (cell, bridge wall, stack)

- Pre-shut down activity – saves time and costs

- Saves maintenance activities (such as: scaffolding, sand blasting, water blasting etc..)

Our On-Line Cleaning Process is SAFE and Environmental Friendly:

- Developed over years of R&D and field experience

- Chemicals are Non-toxic, Non-hazardous, Non-corrosive, Non-poisonous, Non-flammable, Non-explosive, Non-transport regulated

- No damage to metallurgy, refractory, and instrumentation

- Chemicals completely decompound in high temperature

- Chemicals are compatible with all types of furnace or boiler metallurgy

Photo Gallery

Fouled Radiant tubes

.jpg)

On-Line dry chemical cleaning in action – Radiant section

On-Line dry chemical cleaning in action – Convection section

.jpg)

Radiant tubes cleaning process:

note clean areas Vs. dirty areas

.jpg)

Radiant tubes BEFORE cleaning

Radiant tubes AFTER cleaning

Convection tubes cleaning process:

note clean tubes (bottom bundle) Vs. dirty tubes (upper bundle)

.jpg)

Convection section existing openings/windows:

.jpg)

Convection section openings (flanges) made specifically for SENTRO cleaning:

Furnace On-Line Dry Chemical Cleaning (night shift):

note the light plume of white smoke, that appears like steam

SENTROMAX dry chemicals are non-hazmat, non-toxic, not regulated for transport

SENTRO setup near the furnace: Equipment, Chemicals, Air Compressor and Hoses – our footprint is small.

Vapor Phase Chemical Cleaning (Injecting chemicals + steam)

Vapor-Phase Chemical Cleaning

Principles:

- Chemical injected Into steam.

- Continuous injection of fresh chemical.

- Continuous monitoring of hydrocarbon levels.

- De-oiling, degassing & Sulphide oxidation (no Pyrophoric).

- Minimal changes in operational steam-out procedures.

A typical Vapor-Phase Application (Vacuum Tower)

.png)

Vapor-Phase chemical-steam-water manifold

Key Vapor-Phase Advantages:

- Minimizes Down Time

- Reduces Steam Out Duration

- Reduces Maintenance Activity Before and After Decontamination Process

- Environmentally Friendly

- Biodegradable

- Extremely Low Chemical Oxygen Demand (COD) Waste

- Does not make Stable Emulsions

- Minimizes the amount of waste generated

Pre-flushing and Post-flushing advantages

Pre Flushing

- PHelps reduce surface tension and remove free solids.

- PPenetration and softening of Atmospheric Residue.

- PAssures chemical contact of solids in packed sections and dead spots.

Post Flushing

- Assures chemical saturation and neutralization of pyrophoric in large packed sections.

- PHelps to carry out free solids.

- PWill rinse out residual chemical and reduce odor.

- POxidized rinse water helps with effluent disposal.

Steam is traveling upwards. This carries chemicals throughout the equipment, even to the underside trays. Condensation is constantly working downward – also carrying chemicals.

This promotes penetration and oxidation everywhere in the unit.

Pre-flushing and Post-flushing with chemicals allow additional oxidizing and washing treatment.

It is possible still to have untreated deposits deep within some zones, but everything that can be reached WILL be reached.

Combination of Vapor-Phase and bottom circulation

Bottom section of process equipment is liquid filled and circulated with either process pumps if possible or diesel driven high volume circulation pumps.

Top section or OVHD is vapor phased through side stripper or temporary steam connection.

Bottom section of process equipment is liquid filled and circulated with either process pumps if possible or diesel driven high volume circulation pumps.

Top section or OVHD is vapor phased through side stripper or temporary steam connection.

Advantages of the Vapor-Phase and Circulation approach:

Effective

Effective

- Penetration and softening of heavy residuals and asphaltenes.

- Assures chemical contact and reduces the possibility of channeling.

- Will suspend and remove coke scale and particulates.

Efficient

- Results are equal to a cascade or full circulation but with less effluent volume.

- Fewer mechanical connections and less maintenance time.

Photo Gallery

Process Towers recently cleaned by SENTRO’s Vapor-Phase Technology

.jpg)

SENTROKLIN chemical injection via 10 high-pressure pneumatic pumps

.jpg)

.jpg)

Injection point to the unit – chemicals, steam and water

.jpg)

Excellent cleaning results – flushing effluent is clear

.jpg)

SENTRO’s personnel are experienced and professionals in this field

.jpg)

On-site and In-house hydrostatic pressure testing

Hose Assembly Services